- Good Sam Community

- Groups

- Travel Trailer Group

- Forum

- How to treat a Subfloor?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

How to treat a Subfloor?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-27-2019 06:13 AM

We have to replace the entire floor.

We bought a tongue and groove subfloor ( not marine grade) and wanted to know how to treat it and what exactly to use. We are young and inexperienced so product names are greatly appreciated. I've read some people say to seal it but with what? We will be putting vinyl flooring on top of the Subloor. Underneath it will be insulation and then an exterior grade plywood as the base. The exterior plywood will be exposed to weather, should we seal this too or leave it open to "breathe" when it gets wet?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-01-2020 12:24 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-01-2020 07:22 AM

You could also wrap the bottom layer in Darco, a waterproof fabric, before installation.

2015 Skyline Dart 214RB

2018 Silverado Double Cab 4x4

Andersen Hitch

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-31-2019 09:45 PM

If your really worried about it, then use an underlayment

on the vinyl flooring (assuming its plank or similar), i'd suggest something rated for non climate controlled otherwise it can contract in cold environments and separate at the seams.

2017 Impact 312 Toyhauler

2014 Yamaha grizzly 700 (mine)

2013 Yamaha grizzly 550 (hers)

1998 Kawi Prairie 400 (boys)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-31-2019 09:22 AM

Cost/effort/benefit analysis here.

2017 Heartland Torque T29 - Sold.

Couple of Arctic Fox TCs - Sold

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-31-2019 09:20 AM

GrandpaKip wrote:

Most contemporary trailers use the plastic corrugated sheets as the bottom layer that is closest to the road. No sealing, no rot and lower cost. Most people call it an underbelly cover. I have bought some at Home Depot in the past.

I suggest you go take a peek under a trailer at an RV dealer.

^ This is what I was describing, but appears the OP is intending to make a plywood sandwich with foam insulation in the middle on top of the floor framing.

Is this how the trailer was originally built? If not, have you accounted for the additional floor thickness or height?

Bottom line, the water resistance of the bottom plywood is being scrutinized far too closely, IMO. It is not submerged, it is not constantly exposed to the weather from above. It only gets wet while driving in the rain and then is sheltered and dries out.

For example, I have a "temporary" plywood ramp I built into the back of the shop about 9 years ago. wood frame, don't remember if I used treated lumber or not, with a piece of MDO plywood on top. It has been 100% exposed to the wettest weather (Seattle) from above and has yet to rot out.

Pretty much all cargo trailers have exposed plywood on the bottom, some are pressure treated, some traditional plywood or other material like Advantech (exterior grade OSB basically). Have a 15 year old trailer that runs only in the winter (wet/salt/slush) and sits outside. Floor is fine, like new still.

Any exterior glue plywood with a coat of paint, stain, varnish, waterproofing sealer will likely out last the trailer again as it is only occasionally exposed to road spray and sheltered the vast majority of the time.

Barring re-constructing the floor the way RVs are typically built. 1 layer of flooring above the joists, insulation in between the joists and a thin "skin" under the joists, if your doing the sandwich floor...

I'd think 1/2" ply bottom, 1" 30-40psi foam board, 1/2" plywood on top.

2017 Heartland Torque T29 - Sold.

Couple of Arctic Fox TCs - Sold

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-31-2019 06:27 AM

I suggest you go take a peek under a trailer at an RV dealer.

2015 Skyline Dart 214RB

2018 Silverado Double Cab 4x4

Andersen Hitch

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-30-2019 05:57 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-30-2019 05:45 AM

pianotuna wrote:

Hi,

So is there a waterproof plywood?

Yep, if you fiberglass it.

2015 Skyline Dart 214RB

2018 Silverado Double Cab 4x4

Andersen Hitch

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-29-2019 08:38 AM

GrandpaKip wrote:

Most CDX is not suitable for vinyl sheet flooring (telegraphed defects) and has a twist that can difficult to deal with in close quarters.

BC plywood can also be used, though not as flat or smooth as AC.

Good point. For the OPs, also consider snap lock type “floating” flooring. Economical, again much easier to work with, especially in tight quarters and many more aesthetically pleasing options.

2017 Heartland Torque T29 - Sold.

Couple of Arctic Fox TCs - Sold

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-29-2019 07:14 AM

So is there a waterproof plywood?

My ride is a 28 foot Class C, 256 watts solar, 556 amp-hours of Telcom jars, 3000 watt Magnum hybrid inverter, Sola Basic Autoformer, Microair Easy Start.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-29-2019 07:13 AM

It is also horribly expensive.

2018 Coachmen Catalina Legacy Edition 223RBS

1991 Palomino Filly PUP

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-29-2019 05:27 AM

BC plywood can also be used, though not as flat or smooth as AC.

2015 Skyline Dart 214RB

2018 Silverado Double Cab 4x4

Andersen Hitch

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-28-2019 10:01 AM

GrandpaKip wrote:

Marine grade plywood is overkill in my opinion. Exterior AC plywood would work just as well, is less expensive and easier to find. Not necessary to seal it, either.

I would use foam board for insulation if you think it’s necessary. Since we don’t camp in the cold, I would skip it.

Coroplast, a corrugated plastic sheet, can be used to enclose the underbelly.

Some more lack of understanding of plywood grades, types, and properties. Here.

Why spend the big $ for AC for sub flooring. What's the advantage to an A grade sanded surface that's getting covered with flooring? Especially in an old camper.

Agree marine grade is 100% unnecessary unless you're pre planning for leaks that will rot your floor out 15 years from now. But if you insist on pressure treated flooring in a "dry" application, there are cheaper options that what folks are referring to (AB marine grade).

Back to the Tn G thing. Unless you're a good carpenter, I see installing t n G being a challenge in a RV rehab, unless the whole thing is gutted out square box and even then you'll probably lose the tongue on the last piece to fit it.

Don't overthink it. 3/4 CDX plywood is more than sufficient. Or Advantech if you can find it reasonably priced.

One consideration is joist spacing and what was in there and how much the floor flexed or will flex. You may want to orient the sheeting a different direction to prevent any seams in high traffic areas or consider better quality ply (7 or 9 ply) for high traffic area.

So coming full circle, if you're getting AC for the stiffness of it, may be worth it. Only need a few sheets anyway, correct?

I don't have plywood plies by grade memorized, but for the same thickness board, more plies = stiffer. And less flex.

2017 Heartland Torque T29 - Sold.

Couple of Arctic Fox TCs - Sold

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-28-2019 07:30 AM

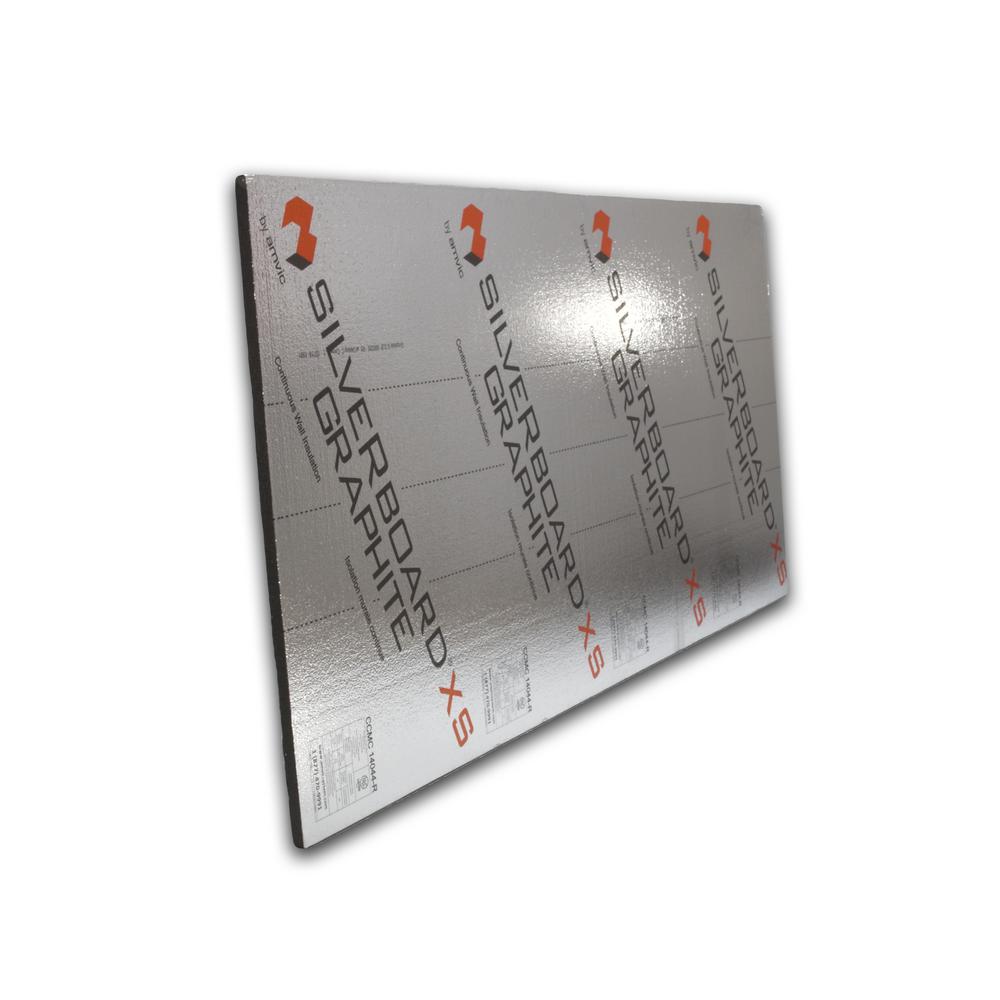

https://www.homedepot.com/p/SilveRboard-0-625-in-x-48-in-x-24-in-72-sq-ft-R-3-Graphite-Radiant-Barri...

My ride is a 28 foot Class C, 256 watts solar, 556 amp-hours of Telcom jars, 3000 watt Magnum hybrid inverter, Sola Basic Autoformer, Microair Easy Start.