- Good Sam Community

- Everything RV

- Technical Issues

- 10/3 Wire split

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

10/3 Wire split

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-07-2020 08:46 AM

I have a 10/3 wire (my 30amp service line) from the inlet to the breaker box and between the two I have a cut in the insulation. I'm wanting to splice the wire and put in a new piece from the inlet to where the cut is which is only about 3ft from the inlet. It would a major pain to replace the entire wire as one piece so I'm thinking about installing a junction box and using wire nuts to piece the wire together.

Is this a bad idea since it is the 30amp line? Will twisted wire with wire nuts hold up to those amps? My other option is a terminal connection but I don't have any experience with those. Your ideas?

Thanks in advance

Scott

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-12-2020 04:40 PM

37,800# GCVWR "Towing Beast"

"HeavyWeight" B&W RVK3600

2016 MobileSuites 39TKSB3 highly "Elited" In the stable

2007.5 Mobile Suites 36 SB3 29,000# Combined SOLD

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-12-2020 05:33 AM

I appreciate everyone's feedback and discussions (arguments) about which is the best way. I've determined from the discussions that the right way is whatever floats my boat as long as the copper is not damaged. For now it is going to get wrapped and down the line maybe it will get replaced with a jbox. However, I'm 95% leaning towards building out a skoolie in the near future so that will end the need for jbox or tape

Cummins12V98 wrote:

HMMMM

No responses.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-11-2020 06:09 PM

No responses.

37,800# GCVWR "Towing Beast"

"HeavyWeight" B&W RVK3600

2016 MobileSuites 39TKSB3 highly "Elited" In the stable

2007.5 Mobile Suites 36 SB3 29,000# Combined SOLD

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-11-2020 08:42 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-11-2020 07:21 AM

MEXICOWANDERER wrote:

There exists SPIRAL WRAP to serve as exactly that, cool around the vulnerable area. The cheap Chinese plastic stuff works OK for cosmetic effect while more expensive Nylon wrap protects against physical bumps, scrapes and cuts.

Butt connectors are available with built-in shrink tubing or a person can stick with a Snuffy Smith Special.

I especially like the marine ones that have some kind of a heat/melt glue in them also.

bumpy

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-11-2020 06:53 AM

Butt connectors are available with built-in shrink tubing or a person can stick with a Snuffy Smith Special.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-11-2020 06:39 AM

MrWizard wrote:

I love silicone self fusing tape

I have been using the 3M brand

I always use it on connections I don't want to re-visit

Will try the F2t tape next time I order some

I wrap new cable ends with it, to seal them, better protection than shrink tubing

Nice some understand the usefulness of these products.

I had an overhead feeder line get chaffed that fed power to an out building. It caused weird electrical issues when it rained. I turned off the power, re attached the support that kept the feeder off the roof and proceeded to properly wrap the chaffed line. Worked GREAT!

Now all you splice fans should I have chopped apart a perfectly good wire and set a couple junction boxes with new cable in-between?????????

37,800# GCVWR "Towing Beast"

"HeavyWeight" B&W RVK3600

2016 MobileSuites 39TKSB3 highly "Elited" In the stable

2007.5 Mobile Suites 36 SB3 29,000# Combined SOLD

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-11-2020 04:41 AM

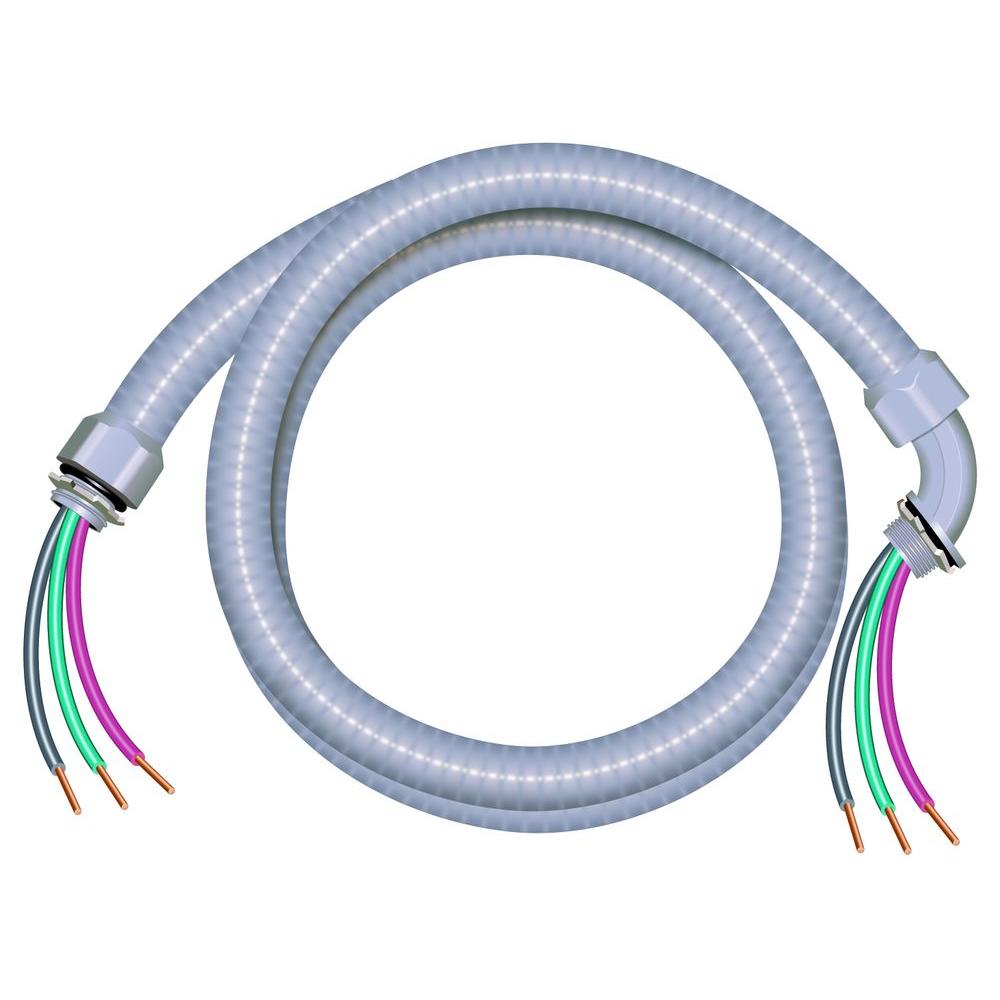

Yes, wirenuts are fine as long as the cables are clamped where they enter the junction box and the box cover is installed.

Click pic for link.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-10-2020 08:11 PM

Mr Wizard, gotta good source? Sorta pricey.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-10-2020 08:06 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-10-2020 01:21 AM

I have been using the 3M brand

I always use it on connections I don't want to re-visit

Will try the F2t tape next time I order some

I wrap new cable ends with it, to seal them, better protection than shrink tubing

But I Can Not understand it for you !

....

Connected using T-Mobile Home internet and Visible Phone service

1997 F53 Bounder 36s

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-09-2020 08:36 PM

NRALIFR wrote:

Bandaids fall off eventually. Fixes do not.

:):)

Use the proper tape I mentioned and it will never fail.

37,800# GCVWR "Towing Beast"

"HeavyWeight" B&W RVK3600

2016 MobileSuites 39TKSB3 highly "Elited" In the stable

2007.5 Mobile Suites 36 SB3 29,000# Combined SOLD

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-09-2020 05:16 PM

IMO wire nuts would be ok for this job. I did that with the shore cord on the 5er we had and the portable Surge Guard. I moved the Surge Guard to be permanently inside.

The shore cord's bitter end was to a junction box before going to the power centre. I undid the shore cord from the junction box. I cut the ends off the Surge Guard and aiming it the right way towards the pedestal end, joined three wires to the junction box.

Now I had two plug ends to play with and the bitter end of the shore cord to link up. I forget why, but I used the two Surge Guard plugs and got it all together using lots of wire nuts. Worked great for over 10 years.

For selling the 5er, I took that out and put the shore cord back where it was OEM. Put the Surge Guard back together with lots of wire nuts 🙂 and now it is inside the Class C still working. ( I use the C's OEM shore cord all inside to the Surge Guard and another cable for the RV to pedestal run. I can also plug into the inverter instead of into the cable that goes to the pedestal for Whole House)

I used mostly those big blue wire nuts because they have the side wings so you can twist harder on them. I didn't know the red ones with no side wings were for 10 AWG as was mentioned. I use red ones for # 8 but find the blue ones can be twisted tighter even with #8. Whatever works! 🙂

on Ford E350-460-7.5 Gas EFI

Photo in Profile

2. 1991 Bighorn 9.5ft Truck Camper on 2003 Chev 2500HD 6.0 Gas

See Profile for Electronic set-ups for 1. and 2.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-09-2020 05:12 PM

Did I write 'part'? Well maybe the part of my head that needs to be shorn every so often.

Repairs? Should suit the sensibilities if the person affected. I've seen individuals to sensitized to perfection that they seemingly anguish over an eighth of an inch out of parallel.

- 50amp wiring question in Technical Issues

- Heartland Cyclone Water Heater in Technical Issues

- Newer RV had "hot" wire screwed to oven and causing chassis to be "hot-electricly"- check yours! in DIY Maintenance

- Atwood hydro flame model 2H2C Two stage Furnace Digital Thermostat in Technical Issues

- Kwikee Level Best Hydraulic Jacks Touch Pad not working in Technical Issues