- Good Sam Community

- Everything RV

- RV Tips & Tricks

- Single screw on dump valve won’t…

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Single screw on dump valve won’t…

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Sep-24-2022 10:03 AM

What can a guy to to ensure it holds it?

- Labels:

-

Seeking Advice

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Sep-27-2022 06:27 AM

ivbinconned wrote:

I have forgotten how to post a picture!

I think I had an app in my old iPad??

If you will follow these directions exactly, it is very easy to post pictures on our forums. One of our moderators, 1492, developed this photo posting app to post your pictures. It works for other internet sites also. There is no need to have a separate hosting site for your pictures in order to use it.

It is very simple to use. Follow these directions exactly.

1. Upload your picture from your computer to the app.

2. Copy the resulting URL.

3. Paste that URL into your post

without ANY changes

. No additions or deletions.Your picture will then appear in your post and be properly sized for use on our forums.:)

Note: Norton Lifelock does not like the site for some reason. I, and others, use it regularly without issue. When I get the red "Dangerous Webpage Blocked" message I just click on "continue to the site" down at the bottom and everything is ok. Have been doing this since 2014.

Hensley "Arrow" 1400# hitch (Sold)

Not towing now.

Former tow vehicles were 2016 Ram 2500 CTD, 2002 Ford F250, 7.3 PSD, 1997 Ram 2500 5.9 gas engine

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Sep-26-2022 04:40 PM

Gdetrailer wrote:

If the cable fits through the collar you linked, it WILL fit through a wire gland.

I agree. now answer this.

You put the Wire Gland on the wire and lock it down.

How is it going to connect to the valve so that it can pull/push it open/close.. Push yes. Pull ... Well the shaft on the valve is not threaded.

Get a collar that just fits over the shaft. line up the holes so the set screw goes through the collar. INTO the shaft and grabs the wire inside. Problem solved... Works as designed..

That's why I suggested it.. The problem is stripped threads in the shaft.. you coudl also re-tap and use a larger set screw but I suspect overtightening will re-strip.

2005 Damon Intruder 377 Alas declared a total loss

after a semi "nicked" it. Still have the radios

Kenwood TS-2000, ICOM ID-5100, ID-51A+2, ID-880 REF030C most times

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Sep-26-2022 06:19 AM

wa8yxm wrote:

I'm thinking it's the set scew and that valve wont' work well with the "Gable glands)

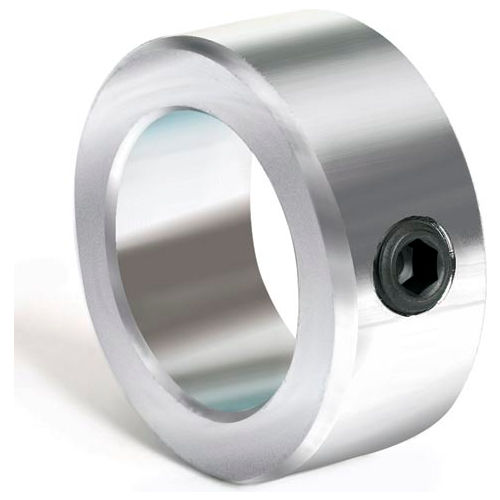

Think a ring around the part the cable goes into with a threaded hole. and a longer set screw in the hole.. As I Said I've seen that before. I just don't know what it is called and I'm not that good at drawing.

Google.. However.. Knows more than I do.

This is the design. Likely the wrong size but it's the design and it's less than 2 bucks

Shaft Collar

If the cable fits through the collar you linked, it WILL fit through a wire gland.

And yes, a company I worked for used those collars on industrial machinery as well as cable glands for the electrical that fed the equipment.

Those collars are typically used on solid hard shafts to prevent them from shifting or moving around. Work good for that application.

They don't work well with applications that involve a hollow item as in the case of the outer jacket sleeve. That is due to limitations of how far the single screw can go in, how much pressure the outer jacket can take in the small spot the screw presses on before deforming to the point that the inside cable is pinched. The valve involved using collars like the one you linked are badly designed and unless you come up with a better clamping arrangement that will always be a failure point.

I am not talking about "status quo" fix, I am talking about making a one time permanent fix so one doesn't have to keep revisiting the problem.

A clamping system that has nearly the entire surface evenly clamped will be much less failure prone in the future.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Sep-26-2022 03:57 AM

Think a ring around the part the cable goes into with a threaded hole. and a longer set screw in the hole.. As I Said I've seen that before. I just don't know what it is called and I'm not that good at drawing.

Google.. However.. Knows more than I do.

This is the design. Likely the wrong size but it's the design and it's less than 2 bucks

Shaft Collar

2005 Damon Intruder 377 Alas declared a total loss

after a semi "nicked" it. Still have the radios

Kenwood TS-2000, ICOM ID-5100, ID-51A+2, ID-880 REF030C most times

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Sep-25-2022 02:11 PM

wa8yxm wrote:

Are youtalking about the set screw that goes into the side of the valve end of the fitting and grips the wire?

You can get a "Collar" that goes over the stem. and has a threaded hole for a slightly longer set screw.. The problem is that though I've seen 'em. and I knwo how to make 'em.. I don't know where to buy 'em.

(Take a nut that just fits. Drill one face. Tap the hole)

Your post made me think of "cable and wire glands" which are typically used as a strain relief/moisture barrier for electrical wires..

Available in different IDs..

Still would have to make a bracket to mount the gland to the valve body.

Variety pack of 35 HERE

If you can measure the OD of the cable jacket you might be able to find a gland of slightly larger ID..

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Sep-25-2022 01:32 PM

You can get a "Collar" that goes over the stem. and has a threaded hole for a slightly longer set screw.. The problem is that though I've seen 'em. and I knwo how to make 'em.. I don't know where to buy 'em.

(Take a nut that just fits. Drill one face. Tap the hole)

2005 Damon Intruder 377 Alas declared a total loss

after a semi "nicked" it. Still have the radios

Kenwood TS-2000, ICOM ID-5100, ID-51A+2, ID-880 REF030C most times

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Sep-25-2022 10:45 AM

Depending on one single screw to put pressure on the jacket to hold the jacket in place will never work for long as you have found out. You need a clamping system that puts pressure on the jacket 360 degrees (your hose clamp setup would be a improvement on a single point of contact).

You can rig up a bunch of different clamping systems that rely on one single point of contact (IE screw into the jacket) on what you have and it will keep failing.

This is the same idea as what you typically find on small engine cable throttles on lawn mowers, they always provide a healthy clamping system to hold the outer jacket from moving that doesn't use a single screw into the jacket..

Not a real good example but here is a pix that may illustrate a bit better..

In the case of this design the outer jacket is clamped between two points without crushing the jacket. The other end goes to the throttle and there is a metal clamp that surrounds the jacket to hold it in place.

If you really want to keep the valve you have, you will need to rig up a permanent metal bracket and clamping system that is capable of surrounding the jacket and attach the bracket to your valve some how.

Otherwise, perhaps bite the bullet and replace with a Valtera valve design like I showed and be done with the mess.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Sep-25-2022 06:48 AM

I think I had an app in my old iPad??

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Sep-25-2022 06:36 AM

What I did now was fasten a small hose clamp to the cable and tightened a tarp strap to the cable to help hold with tension to counter the force that wants to push the cable out of its holder when shutting the valve.

I’ll try to post a picture.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Sep-24-2022 11:09 AM

Outer jacket should be held in place by the plastic clamp/holder with two screws (see item I have circled in red)

Only the center wire that moves the valve gate should be connected to the gate with one screw.

With that said, cable operated valves are known to have reliability issues, if possible replace with a standard non cable operated valve..

On edit..

Found installation instructions for the remote valve to cable..

HERE

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Sep-24-2022 10:24 AM

My ride is a 28 foot Class C, 256 watts solar, 556 amp-hours of Telcom jars, 3000 watt Magnum hybrid inverter, Sola Basic Autoformer, Microair Easy Start.