- Good Sam Community

- Groups

- Truck Camper Group

- Forum

- Happijac lubrication

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Happijac lubrication

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-17-2009 07:37 PM

First you have to make a little tool like this. An old hanger works good. This will serve two purposes, explanations following.

Remove the two screws that hold on the motor.

Pull the motor off the jack.

Pull out the spring loaded socket.

Remove the lever and pin...a pair of flush wire cutters works well. Wedge them underneath and they pop right out.

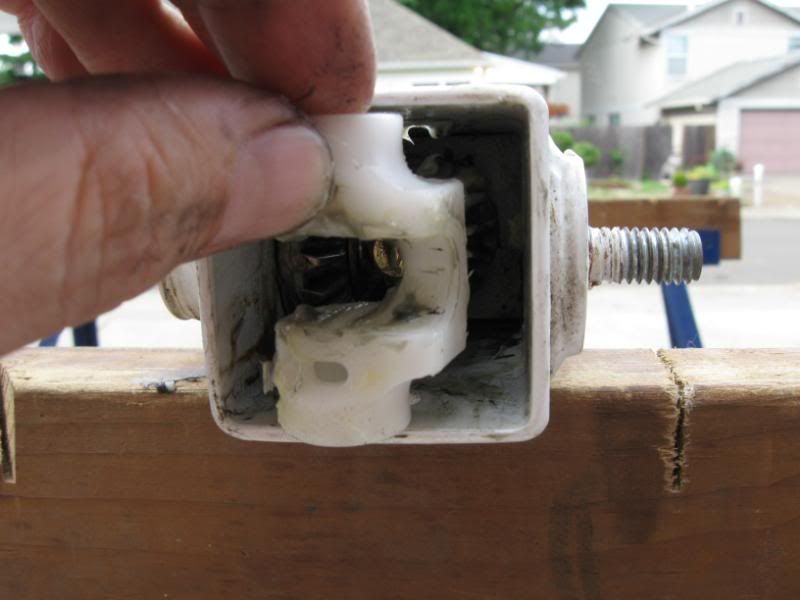

Remove the internal plastic manual mechanism...note how this is installed. one side has a round hole and the other an oval shape where the lever goes.

There is a "C" clip here, you need to remove it with the little tool you made. Just put it in from the side and pull back. It will pop right out.

Once you get the clip off then pull out the manual socket.

This is the hole in the socket that is to be oiled, but as you can see in the next few pics, the only thing that is being lubed is the socket itself.

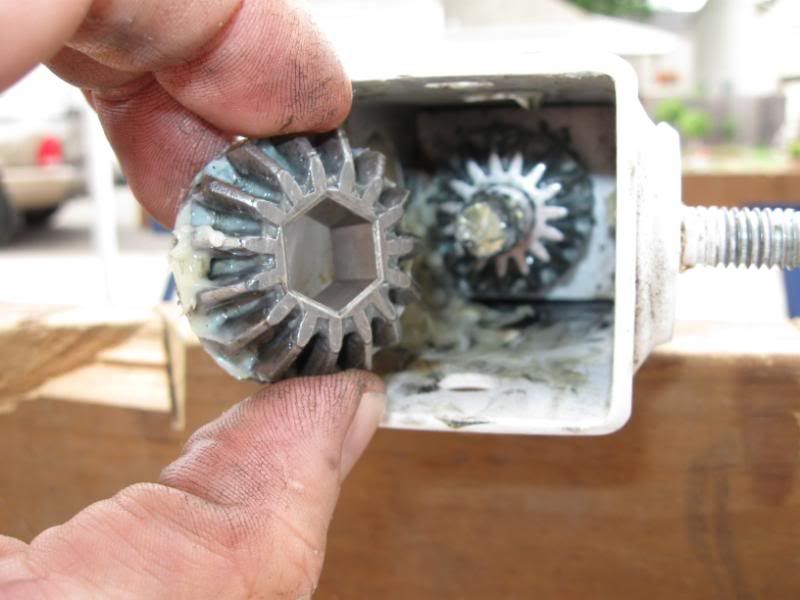

Once you pull out the socket, remove the manual gear.

Now as you can see the oil really goes nowhere. There is actually a lot of grease here. What your going to do next is pull this gear off that shaft straight towards you. Use that tool again to hook the gear from behind and pull it. You may have to do it a few times, the shaft gets a little burr on it but if it gets stuck ,just push it down and keep yanking, it will come off!

Once the gear comes off, this is what the back looks like. It has two slots. The slot that has the closed ends is what holds the pin in place. IT IS IMPORTANT YOU PUT THIS BACK TOGETHER THE WAY IT COMES APART!

Rotate the shaft so the pin is facing towards the corner and pull it out.

Now pull the leg assembly out of the jack housing.

Get ready to inspect and re lube.

Pull this cinch spring off and inspect this bearing.

Use an air ratchet or drill to turn the worm screw all the way out, inspect and re lube.

Re-assembly is just the opposite of the tear down. I found that even though this jack was sticking on me, it was still pretty well lubed, but maybe not enough.....Hope this dispels any unknown facts as to how these things work. One other note is that if the worm drive of the leg was to wear out...seems like you should be able to replace it rather than the whole jack. MMMMMM...haven't got to that yet but I wonder if they sell it seperatly? Does any one know?

- Labels:

-

Truck Campers

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-01-2022 06:53 PM

I guess another option would be to put fittings near the top on all 4 sides and force enough grease through to force out the grime.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-20-2021 08:42 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-08-2021 11:07 AM

You could certainly try putting the tube into a clamped holder, and apply a minimal amount of pressure with a hydraulic jack while you attempt to move it. If you do manage to move it then, at least you will know which way the bend might be.

2012 Winnebago Impulse Silver 26QP

2005 16.6 Double Eagle

2018 Jeep Wrangler JK

previously Snowbird Campers,

Triple E Motorhome and Fifth Wheel

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-08-2021 07:17 AM

On the other hand, 3 of the jacks work fine, and the jack in question was on the front right side, which shows no sign of damage. And I can't detect any deflection in the stuck jack. But yes, with tolerances so tight, that could certainly be the problem. And previous owner might have swapped it around.

Glad to hear JimK got 18 years out of his. That would do me.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-07-2021 02:16 PM

Regarding Exterior Finish: (for others) - there was a period of time where Happijac tubes were rusting badly via small exterior corrosion cells, I believe due to bad coating, I had to disassemble the jacks and take the tubes in to be sandblasted and powder coated. This fixed the problem. I wrote to Happijac but they did not answer me.

Regarding Bound-up tubes: I'm sorry for your trouble. Need to ask, is this just one tube or all 4? Is it at all possible you backed into/hit something and may have bent the tube(s)? (It wouldn't take much deflection to mess this up).

Regarding motors and water entry: It supposedly never rains in So Cal but I've had to rebuild several motors for this. Can't explain why, but motors were seized up solid with clear signs of water entry and damage. FYI, the little "drill motor" size bearings were readily available on Amazon for as low as 10qty/$12.99; (Same size as used in kid's "spinners") - the local NAPA store wanted $70 for just one bearing! It is my experience that years ago you could send in motors for exchange/rebuild but nowadays they will only sell you a complete replacement motorhead assembly, no exchange possible.

I'm overall happy with Happijac; but I'd be happy paying a little more for some extra Zerk grease nipples or oil lubrication ports, if that would assure longer life/ease of maintenance.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-07-2021 01:43 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-07-2021 01:19 PM

Because it's no longer held in place at the top (and no longer trying to move the stuck inner tube) I can crank it down about an inch, so there's free space between the top of the inner worm drive mechanism and the welded plate that serves as a stop when everything is properly assembled. Which in turn means that I can tap on the foot end and move the inner tube upwards about an inch. Then crank at the top again, make room, tap at the bottom... and so on, gradually compressing the whole rig, pouring in penetrating oil as I go. I'm hoping to free it up with the movement and the oil.

So: I can move it in, but can't pull it out. I'm thinking of trying a come-along on the pulling end if it stays stubborn. Maybe donate it to a tractor-pulling competition, LOL

For what it's worth, the inner tube -- the 30 inches or so that I've had out -- is clean, smooth, in good shape, no rust. That outer tube must be a mess inside.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-06-2021 09:31 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-06-2021 09:08 AM

1999 Bigfoot 1011

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-06-2021 09:04 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-05-2021 08:39 PM

Would waxing the legs help?

Or shooting them with silicone type sprays?

Having a cover for the motor head units while stored, if outside?

To be honest, I'm a bit nervous/surprise at some of the experiences posted here. Certainly sound like these units need to be babied right from day one.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-05-2021 08:23 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-05-2021 02:47 PM

'02 GMC DRW D/A flatbed

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-05-2021 11:57 AM